Commercial refrigeration failures can disrupt restaurant operations quickly. When a cooler or freezer goes down, food safety is immediately at risk, inventory can be lost, and service may need to stop. In most cases, these failures are not sudden accidents — they develop over time due to wear, environment, or missed maintenance.

This guide explains the most common commercial refrigeration failures restaurants face, why they happen, and how proactive maintenance helps prevent costly breakdowns.

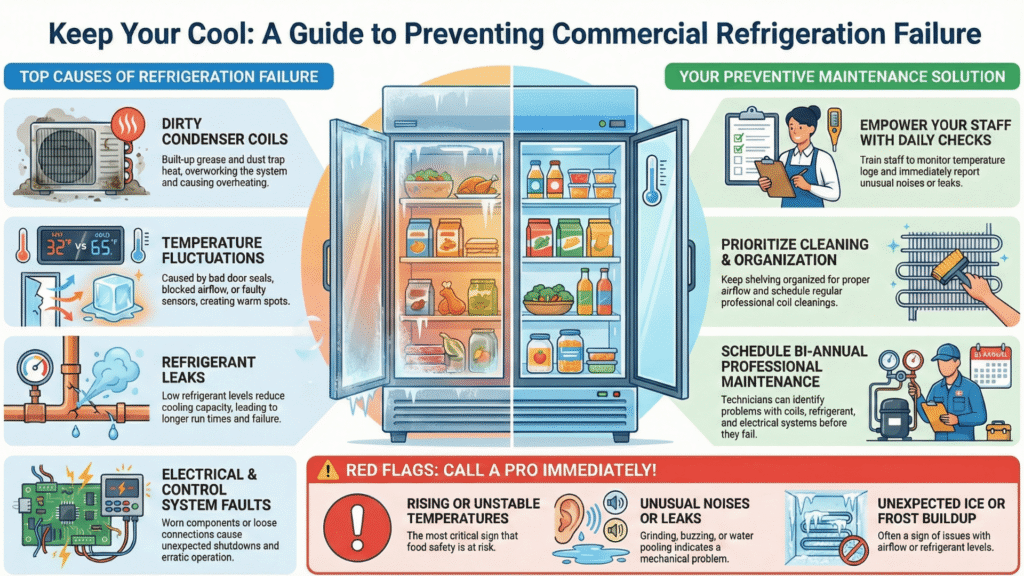

1. Dirty condenser coils

Dirty condenser coils are one of the leading causes of refrigeration failure in restaurants. In commercial kitchens, grease, dust, and airborne debris build up quickly. When coils cannot release heat properly, the system overheats and the compressor is placed under constant strain.

Over time, this leads to reduced cooling performance, higher energy bills, and eventual equipment failure.

How to prevent this issue

- Clean condenser coils on a regular schedule

- Increase cleaning frequency in high-grease kitchen environments

- Include professional coil cleaning as part of routine commercial refrigeration servicing

Proper coil maintenance is a core part of professional commercial refrigeration service and should never be overlooked.

2. Temperature fluctuations and warm spots

Inconsistent temperatures inside a walk-in cooler or freezer are early warning signs of system trouble. Warm spots can cause food to spoil even when the unit appears to be running.

Common causes include:

- Faulty thermostats or temperature sensors

- Restricted airflow due to overstocking

- Worn or damaged door gaskets allowing cold air to escape

How to prevent this issue

- Keep shelving organized to allow proper airflow

- Inspect door seals regularly for gaps or cracking

- Monitor temperature logs daily

- Schedule periodic inspections of sensors and controls

Ongoing temperature issues often indicate the need for professional walk-in cooler or freezer repair before food safety is compromised.

3. Refrigerant leaks or low refrigerant levels

Refrigerant is essential for maintaining proper cooling temperatures. When refrigerant levels drop due to leaks or system wear, cooling capacity declines. This problem usually develops gradually, making it easy to miss until performance is severely affected.

Warning signs may include longer cooling cycles, ice buildup on coils, or equipment running continuously without reaching set temperatures.

How to prevent this issue

- Schedule routine inspections by licensed refrigeration technicians

- Address performance changes early rather than waiting for failure

- Never attempt refrigerant handling without proper certification

Refrigerant problems always require professional commercial refrigeration repair and should be addressed immediately.

4. Electrical and control system failures

Commercial refrigeration systems rely on electrical components, sensors, and control boards to operate correctly. Electrical failures can cause units to shut down, short cycle, or operate unpredictably.

These issues are often caused by loose connections, worn components, or power fluctuations over time.

How to prevent this issue

- Include electrical inspections during scheduled maintenance visits

- Investigate recurring error codes or breaker trips promptly

- Avoid repeated system resets without professional diagnosis

Early electrical inspections reduce the risk of unexpected shutdowns and costly emergency repairs.

5. Lack of regular preventive maintenance

Many commercial refrigeration failures occur simply because routine maintenance is delayed or skipped. Small issues that could be corrected early often turn into major breakdowns when systems are not inspected consistently.

Preventive maintenance helps:

- Identify problems before they cause downtime

- Reduce emergency repair costs

- Extend the lifespan of refrigeration equipment

- Improve energy efficiency

Restaurants that invest in restaurants that invest in scheduled preventive maintenance experience fewer failures and more predictable operating costs.

How restaurants can reduce refrigeration breakdowns

Restaurants can significantly reduce refrigeration failures by:

- Performing daily temperature checks

- Keeping equipment clean and well-organized

- Scheduling professional inspections at least twice per year

- Increasing service frequency before summer

- Training staff to report unusual noises, leaks, or temperature changes early

Operations that rely heavily on ice production should also include routine ice machine servicing as part of their maintenance plan.

When to call a professional immediately

Immediate service is recommended if you notice:

- Rising or unstable temperatures

- Unusual grinding or buzzing noises

- Water leaks or pooling near equipment

- Ice or frost buildup in unexpected areas

- Repeated system shutdowns

Delaying professional service often results in higher repair costs and avoidable food loss.

Professional commercial refrigeration service in Calgary

At Express Refrigeration, we help Calgary restaurants prevent refrigeration failures before they disrupt operations. Our team provides dependable service for walk-in coolers, freezers, ice machines, and complete commercial refrigeration systems.

If your equipment is showing warning signs or is due for routine servicing, early action can prevent costly downtime.

Contact Express Refrigeration today to schedule service or request expert advice