When your commercial ice machine stops producing ice, it’s more than just an inconvenience—it can bring your entire operation to a halt. Whether you run a busy restaurant, a hotel, a healthcare facility, or a bar, reliable ice production is essential to maintaining service quality and meeting health standards.

At Express Refrigeration, we’ve helped countless Calgary businesses get their ice machines back online quickly. In this comprehensive guide, we’ll walk you through the most common reasons why ice machines fail, what you can troubleshoot safely, and when it’s time to call in the professionals.

Why Your Commercial Ice Machine Stopped Working

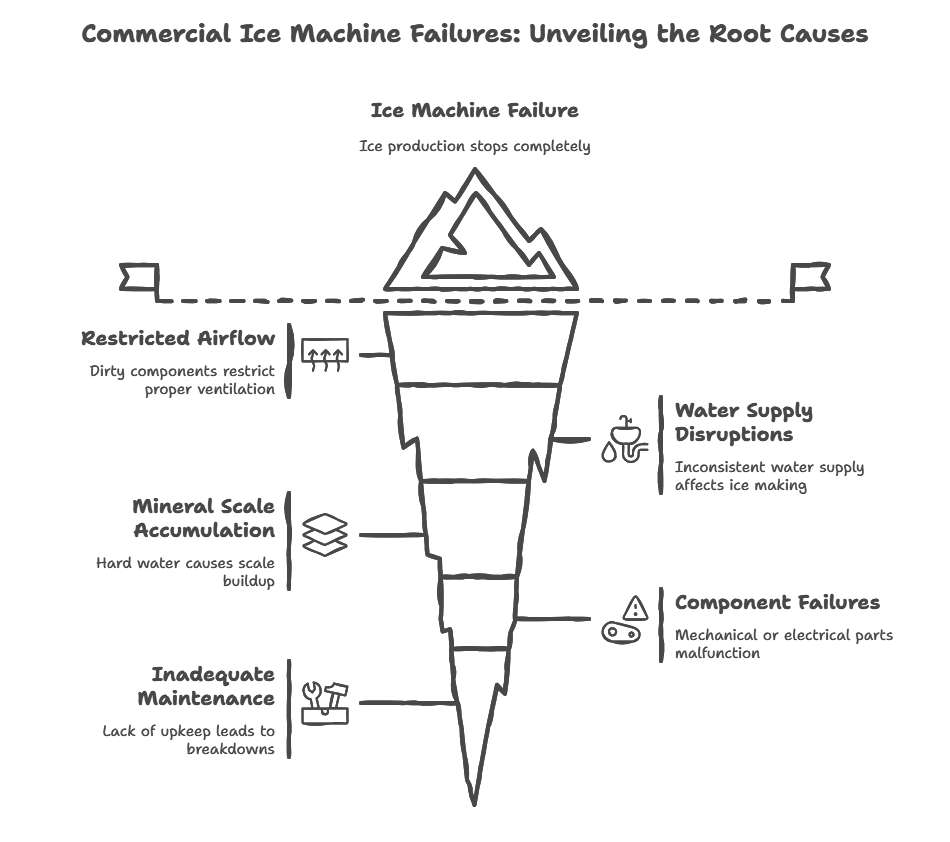

Commercial ice machines are complex pieces of equipment that depend on several systems working in harmony: proper airflow, consistent water supply, and precise refrigeration cycles. When even one component malfunctions, ice production suffers or stops completely.

The most frequent culprits behind ice machine failures include restricted airflow from dirty components, water supply disruptions, mineral scale accumulation from hard water, mechanical or electrical component failures, and inadequate preventive maintenance. Understanding which issue you’re facing is the first step toward getting your machine back in service.

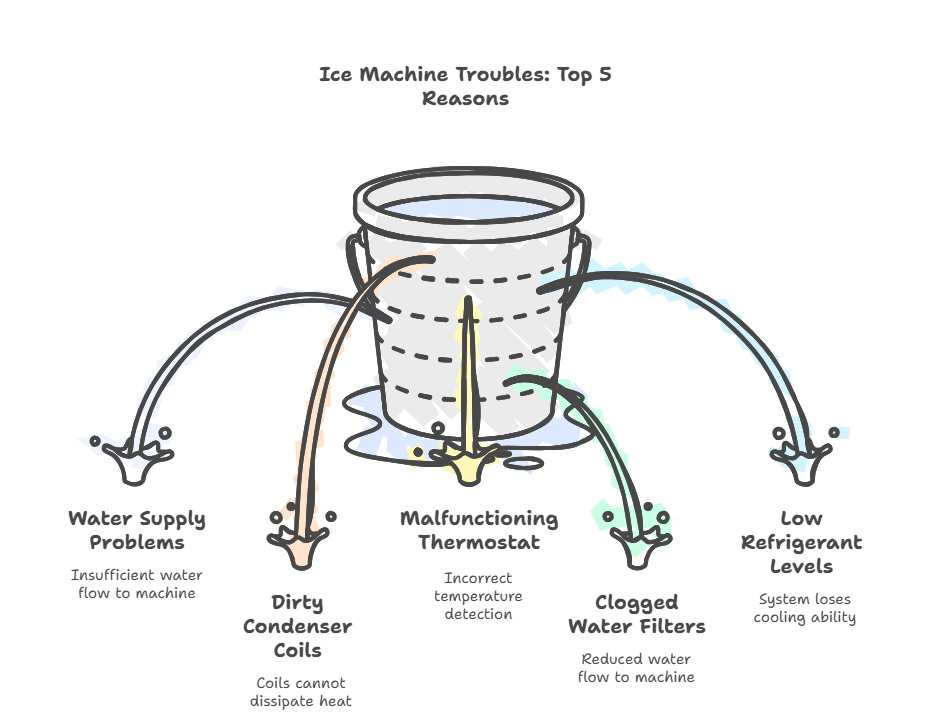

The Top 5 Reasons Your Ice Machine Isn’t Making Ice

1. Water Supply Problems

Your ice machine requires steady water pressure and flow to operate correctly. If the water line becomes partially closed, clogged with sediment, or frozen due to temperature issues, ice production will slow dramatically or cease altogether.

Start by verifying that the water shut-off valve is completely open—sometimes it gets accidentally turned during routine cleaning. Next, examine your water filters for visible blockages or sediment buildup. Finally, inspect the supply lines themselves for any kinks, bends, or signs of freezing, particularly if your machine is located near exterior walls or in cooler areas of your facility.

If you’ve checked all these elements and water flow remains inconsistent, it’s time to schedule a professional inspection. Hidden blockages or pressure issues require specialized diagnostic equipment.

2. Dirty Condenser Coils

This is perhaps the single most common cause we encounter when businesses call us for commercial refrigeration repair. Condenser coils accumulate dust, grease, and airborne debris over time, especially in busy kitchen environments. When coils become coated with this buildup, they can’t dissipate heat efficiently, causing the entire system to overheat and shut down as a protective measure. This is especially common in Calgary commercial kitchens, where grease, dust, and temperature fluctuations accelerate condenser buildup.

Regular condenser coil cleaning is one of the most effective preventive measures you can take. In high-volume food service environments, coils should be cleaned monthly. Even in lighter-use settings, quarterly cleaning will significantly improve efficiency and prevent unexpected breakdowns.

3. Malfunctioning Thermostat or Control Board

Modern ice machines use sophisticated electronic controls to monitor temperatures and manage the freeze cycle. When thermostats become inaccurate or control boards develop faults, they may incorrectly detect conditions that trigger a shutdown or prevent the ice-making cycle from starting.

You might notice your machine running continuously without producing ice, or producing ice cubes of inconsistent sizes and shapes. Some machines will cycle on and off repeatedly without completing a full production cycle. These symptoms point to control system issues that require professional diagnostics and repair—attempting to adjust these components without proper training can cause additional damage and void warranties.

4. Clogged Water Filters

Calgary’s water contains minerals that accumulate in filters remarkably quickly, particularly in high-volume operations. When filters become clogged, water flow decreases, leading to slower ice production, smaller or hollow ice cubes, and premature machine shutdowns.

Water filter replacement should be part of your regular maintenance schedule. Depending on your water hardness and production volume, filters typically need replacement every three to six months. Keep spare filters on hand so you can swap them immediately when you notice production declining. If your commercial kitchen equipment is experiencing widespread issues, water quality may be affecting multiple systems.

5. Low Refrigerant Levels

Refrigerant is the lifeblood of your ice machine’s cooling system. When leaks develop or the refrigerant charge drops below optimal levels, the system loses its ability to freeze water effectively. This problem typically develops gradually, so you might first notice longer freeze cycles or softer ice before production stops entirely.

Refrigerant issues are strictly the domain of licensed technicians. Attempting to add refrigerant without proper EPA certification and equipment is illegal and dangerous. If you suspect a refrigerant problem, contact Express Refrigeration immediately for professional ice machine repair.

It’s worth noting that if your ice machine is part of a larger refrigeration system, problems may be affecting your walk-in coolers and freezers as well.

Safe Troubleshooting Steps Your Staff Can Perform

Before calling for service, your team can safely check a few basic items that sometimes resolve production issues:

Power and electrical: Verify the unit is receiving power and check your electrical panel for tripped breakers. Reset any tripped breakers once, but if they trip again, stop and call for service.

Water supply: Confirm all water shut-off valves are fully open and check that water is reaching the machine.

Airflow: Look for obstructions around air intake vents and ensure nothing is blocking airflow around the unit. Many ice machines need several inches of clearance on all sides.

Filters and cleaning: Check when filters were last replaced and ensure they’re due for service according to your maintenance schedule.

Environmental conditions: Verify the ambient room temperature is within the manufacturer’s specifications. Ice machines in overheated kitchens will struggle or fail.

If these basic checks don’t restore ice production within an hour, stop troubleshooting. Continued operation of a malfunctioning ice machine can cause compressor damage or other expensive failures.

When to Call Express Refrigeration Immediately

Certain symptoms indicate serious problems that require immediate professional attention:

- Complete loss of ice production despite basic troubleshooting

- Water leaking from the machine or pooling underneath

- Unusual grinding, squealing, or banging noises

- Error codes displayed on the control panel

- Ice that appears cloudy, tastes off, or has an unusual texture

- The unit repeatedly trips breakers or shuts down unexpectedly

- Visible frost buildup in unusual locations

Delaying professional service when these symptoms appear often leads to cascading failures. A small refrigerant leak can damage the compressor. Water leaks can create mold issues and damage flooring or nearby equipment. Acting quickly minimizes repair costs and downtime.

The Value of Preventive Maintenance Programs

Most ice machine failures are preventable with regular professional maintenance. A comprehensive preventive maintenance program addresses problems before they cause breakdowns, especially during your busiest seasons when you can least afford downtime.

Professional maintenance visits typically include thorough condenser coil cleaning to maintain optimal heat transfer, complete water system descaling to remove mineral buildup, sensor and thermostat calibration to ensure accurate operation, electrical component inspection to catch developing issues, and comprehensive performance testing to verify the machine is operating at peak efficiency.

We strongly recommend scheduling maintenance before summer, when ice demand peaks and temperatures rise. A well-maintained machine will handle increased production demands without strain, while a neglected unit is likely to fail precisely when you need it most.

Why Calgary Businesses Trust Express Refrigeration

Express Refrigeration has built our reputation on fast response times, accurate diagnostics, and lasting repairs. We understand the operational pressures of commercial food service and hospitality environments—when your ice machine is down, you’re potentially turning away customers and risking health code violations.

Our technicians service all major ice machine brands and models across Calgary and surrounding areas. We work with restaurants and bars that depend on consistent ice for beverages, hotels and hospitality venues that need ice for guest rooms and catering, healthcare facilities with strict sanitation requirements, and commercial kitchens and food production facilities operating at high volume.

We carry common replacement parts on our service vehicles, which means we can often complete repairs in a single visit. Our team stays current on the latest ice machine technology and troubleshooting techniques through ongoing manufacturer training.

Protect Your Investment and Your Operations

An ice machine that isn’t making ice represents a threat to your daily operations, customer satisfaction, and bottom line. While your staff can safely perform basic troubleshooting, complex issues require professional expertise and specialized tools.

The key to avoiding emergency situations is acting early. If you notice declining ice production, unusual noises, or any of the warning signs discussed in this guide, don’t wait for complete failure. Early intervention typically means simpler, less expensive repairs.

By partnering with Express Refrigeration for both emergency repairs and preventive maintenance, you protect your equipment investment and ensure reliable ice production year-round. Our team is ready to help you maintain peak performance and avoid costly downtime.

Is your ice machine underperforming or completely down? Contact Express Refrigeration today for fast, professional service across Calgary. We’re here to keep your operation running smoothly.